|

CLOWN says "Rising Rate is a band aid" |

|

|

Fuel Pressure Regulators |

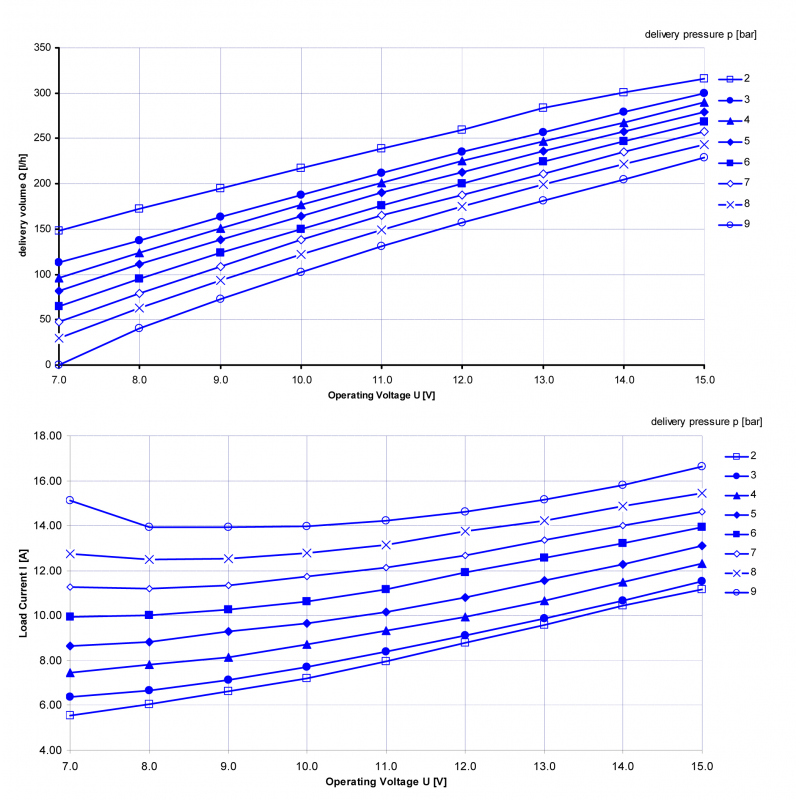

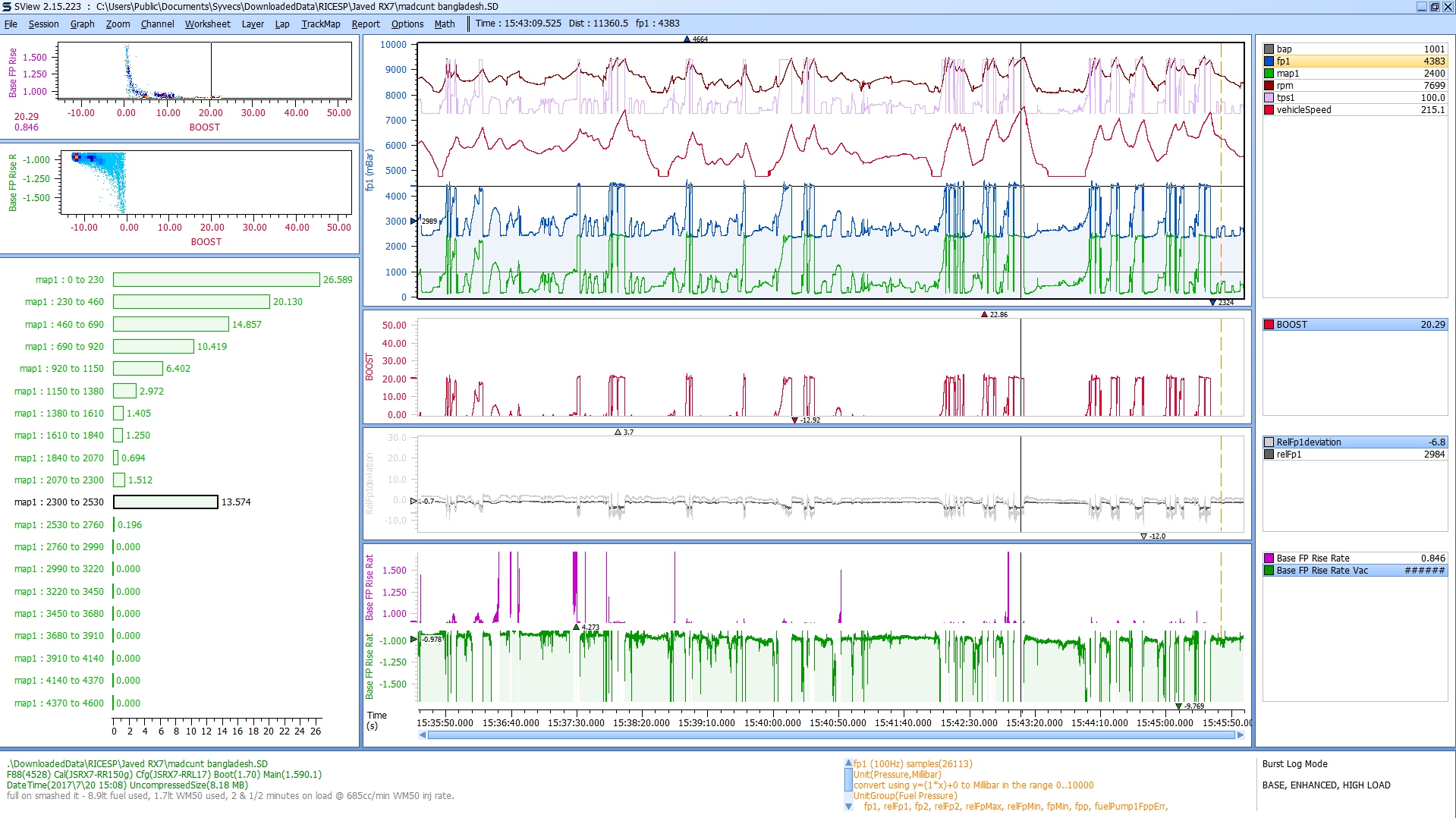

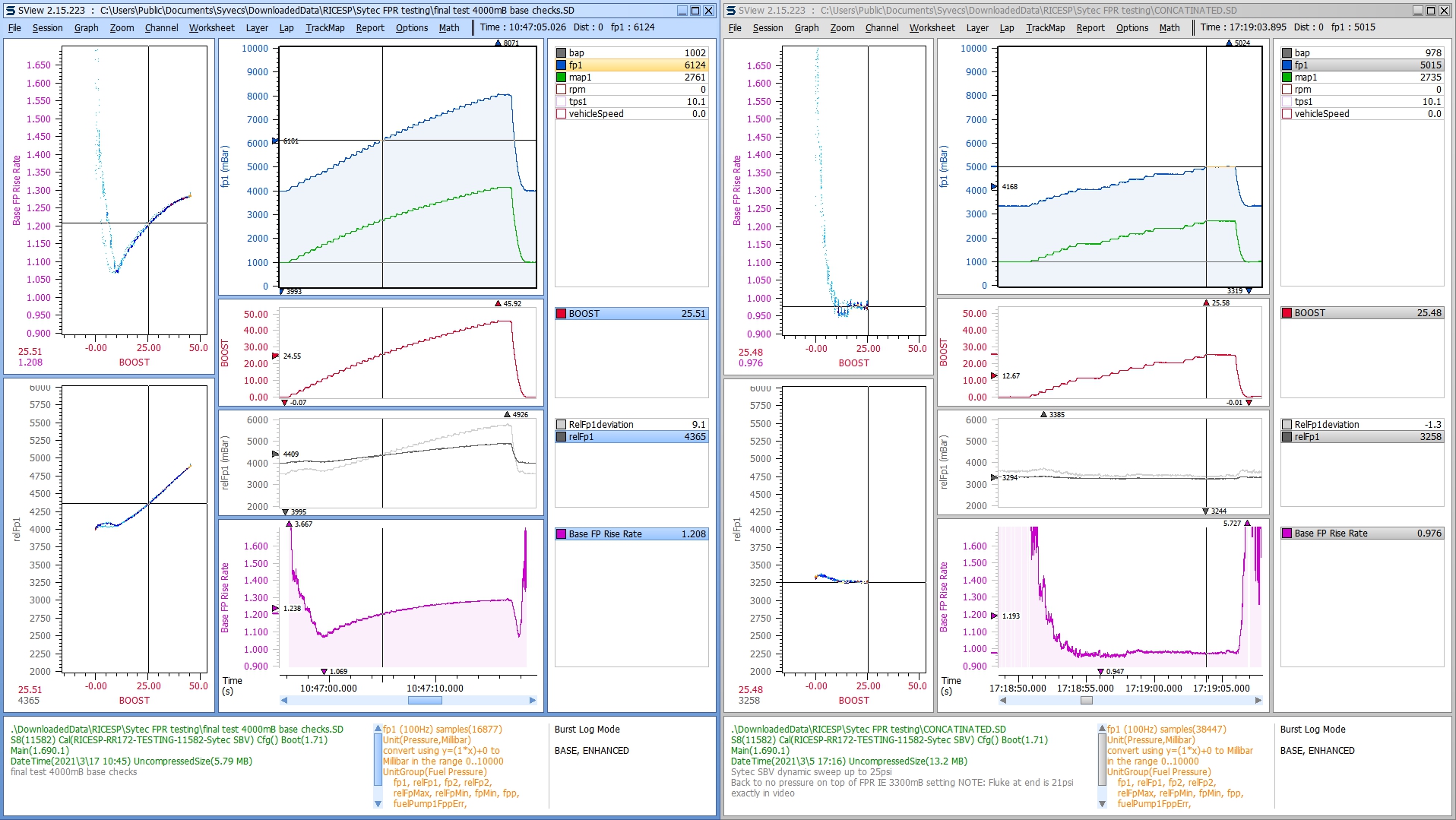

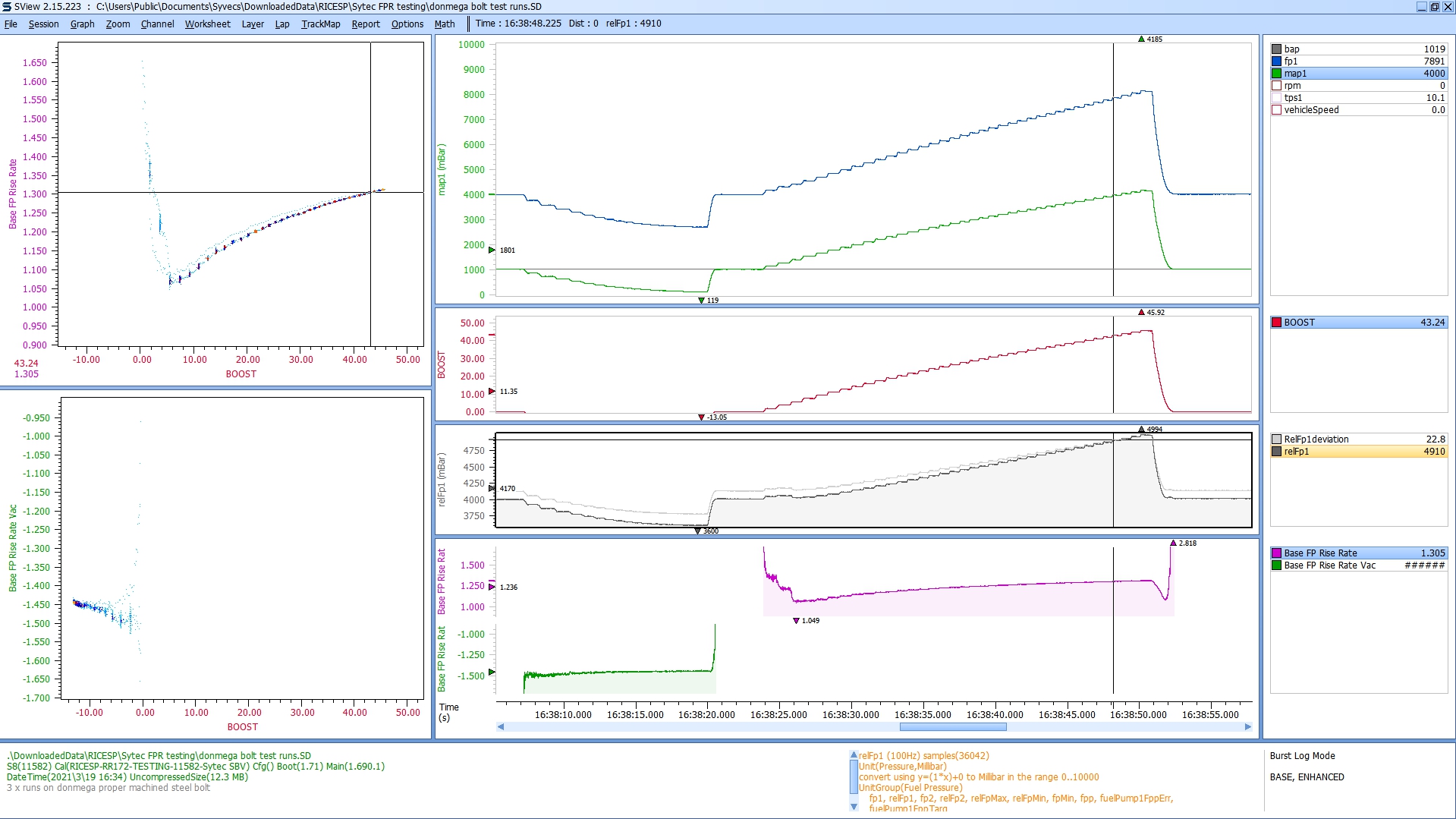

Rice Racing - Fuel Pressure RegulatorsThis is such a fundamental basic of a port injection system that it needs to be addressed properly, so what better way than with some real 'Facts' to debunk the 'Fiction' seen spurting out the mouth/peanut brain on majority talking head sponsored internet 'www dot #fag' world of shit that proliferates today. What is fuel pressure and why is it important:The port fuel injector requires a head of pressure to help atomize its fuel, the engine itself needs an injector/s that are of adequate capacity (function of pressure) not just to satisfy projected power settings but just as importantly to allow adjustment of things like injection angle and to counter range variations (safety margin) say unexpected lower pressure which can and does happen in the real world for various reasons. How to do this or work it out more correctly is NOT easy, its not something to be trusted to a senile or kiddie on-line bullshit blogger putting up kinder garden math, or others articles with worthless self valued opinion based commentary dressed up as knowledge, then drawing conclusions which are never validated. You have been warned ! trust these clowns at your own risk. Each engine has its own requirements:How often is the event scheduled? (360 or 720 CA), what fuel type is it? what is the flow range of the pumps? what are the tertiary considerations (BSFC, AFR, Thermal Eff, etc etc)? You cant Google this shit, you need to know it yourself and understand it. The FPR or fuel pressure regulator is one of the most miss understood items there is. Its functions and operation can be tailored to suit, just depends on what you want from it. Simpletons say: "Has to be 1:1 otherwise its shit" NO CLOWN! the only thing that is shit is that you did not complete basic schooling to a satisfactory level.... To know what is better or ideal, you need the tools to do this and understand the whole system, every part of it. Once you do then its very clear that the ideal is a rising rate and not a 1:1. A basic histogram of your chosen clients typical running of their car will show you where the averages of time are spent on the manifold pressure curve (and therefore fuel pressure curve). It is not uncommon to see 98%+ of time spent below 1000mB (0 psi boost for Retardistan residents at sea level). Even an extreme usage example will spend over 80% of time here. Track only ones well it depends on layout, but reverse the last figure for one with high average speed lap time. Now with that little nugget in your back pocket I ask you, why would you run a 1:1 regulator when you can't do things like, quasi increase fuel injector size, reduce pump wear and tear (for up to 98%+ of conditions!), decrease overall stresses on the whole system to suit the majority of operational life, especially in a 'street car' application. The only reason you would run a 1:1 is cause you listen to Mr Turbo Stupid or Ms Race Retarded arse clown who lives off an I-Phone. Here is a proper sheet (in GagTube videos below), made through qualified knowledge, not gained via pay to play on line 'education' and a picture of a RR massaged Rising Rate FPR optimized to run at the listed pressure ranges. NOTE: This originally was advertised and purchased as and I quote "1.7:1 Rising Rate". It was not (actually showed 0.97:1 on boost) so you really need to have the ability to check these things, understand them, modify and tweak to be what you need. link on discussion and some more detailed pictures. Below showing DON V Original supplied (remember meant to be 1.7:1 *claimed*) On boost it was less than 1:1 !

|

| Home | | About Us | | Products | | Customer Cars | | Technical FAQs | | Links |