|

Bespoke Calibrated Lambda Sensors |

|

|

NTK Lambda Sensors |

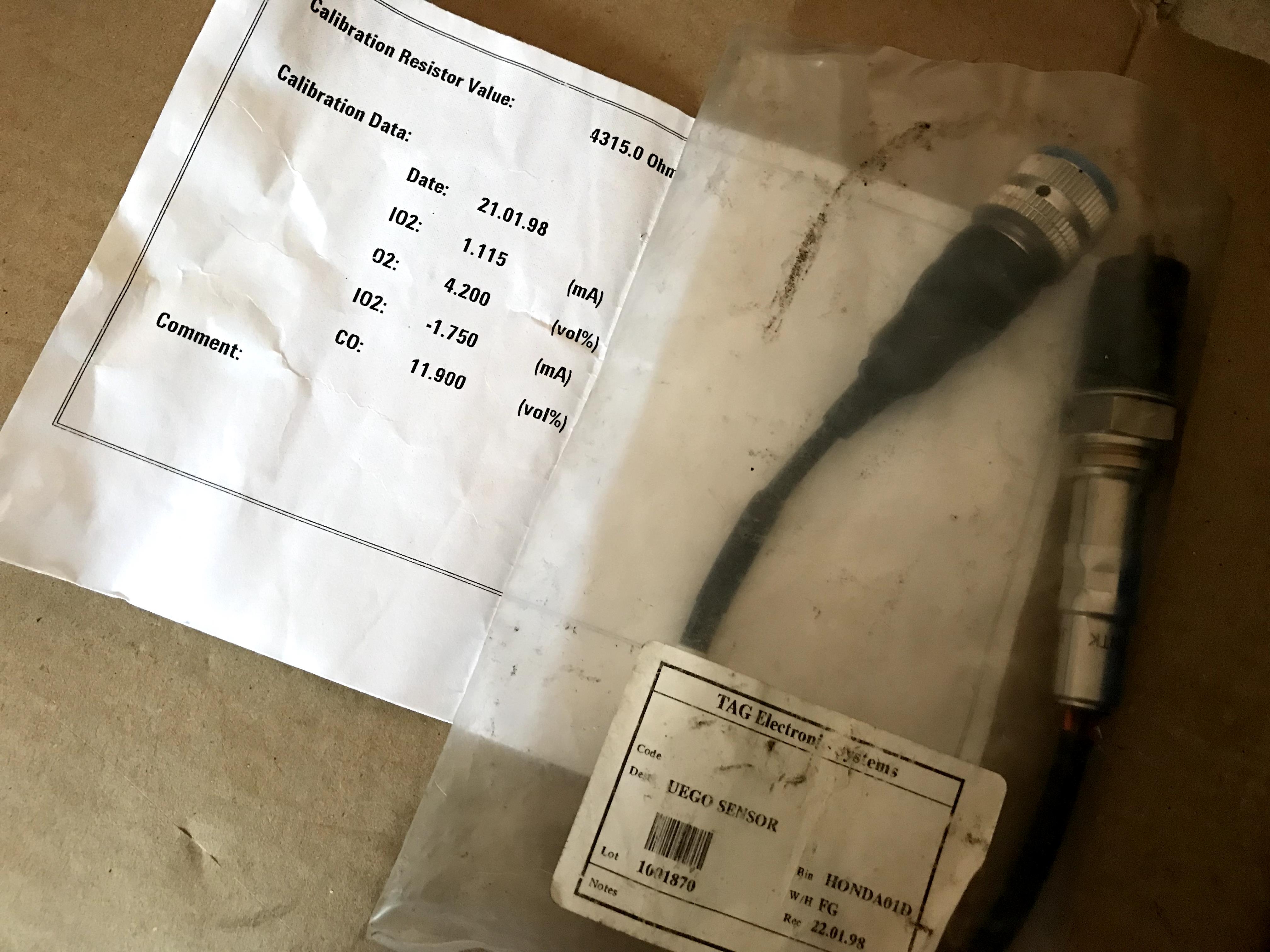

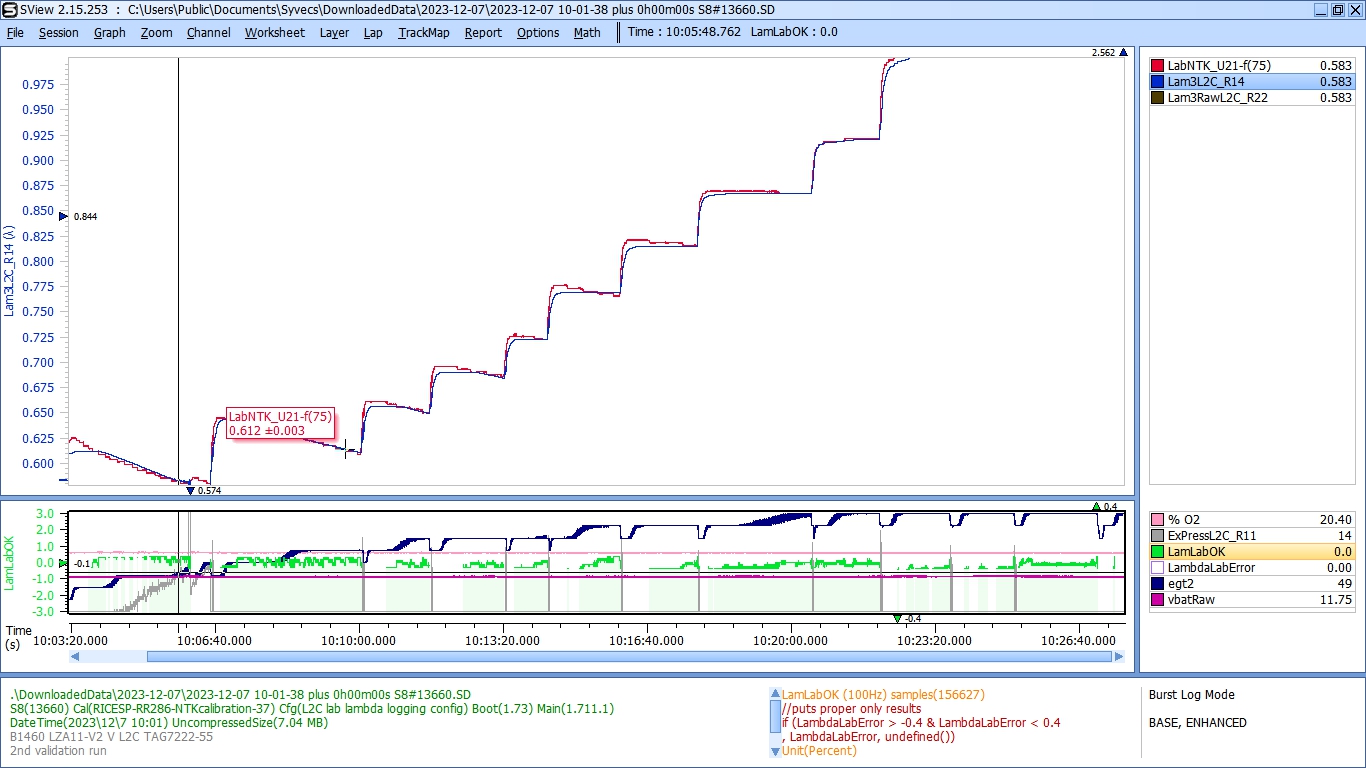

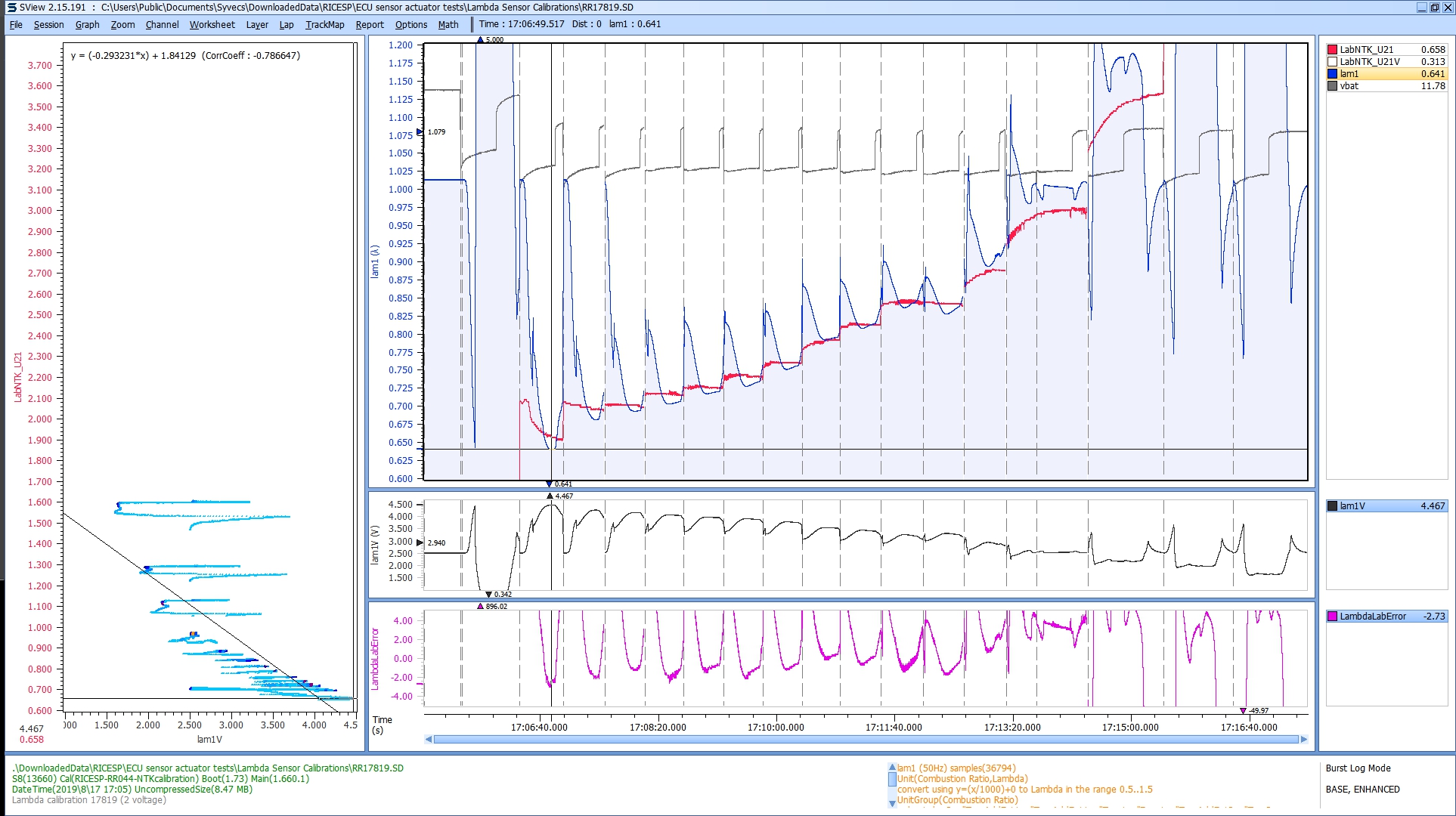

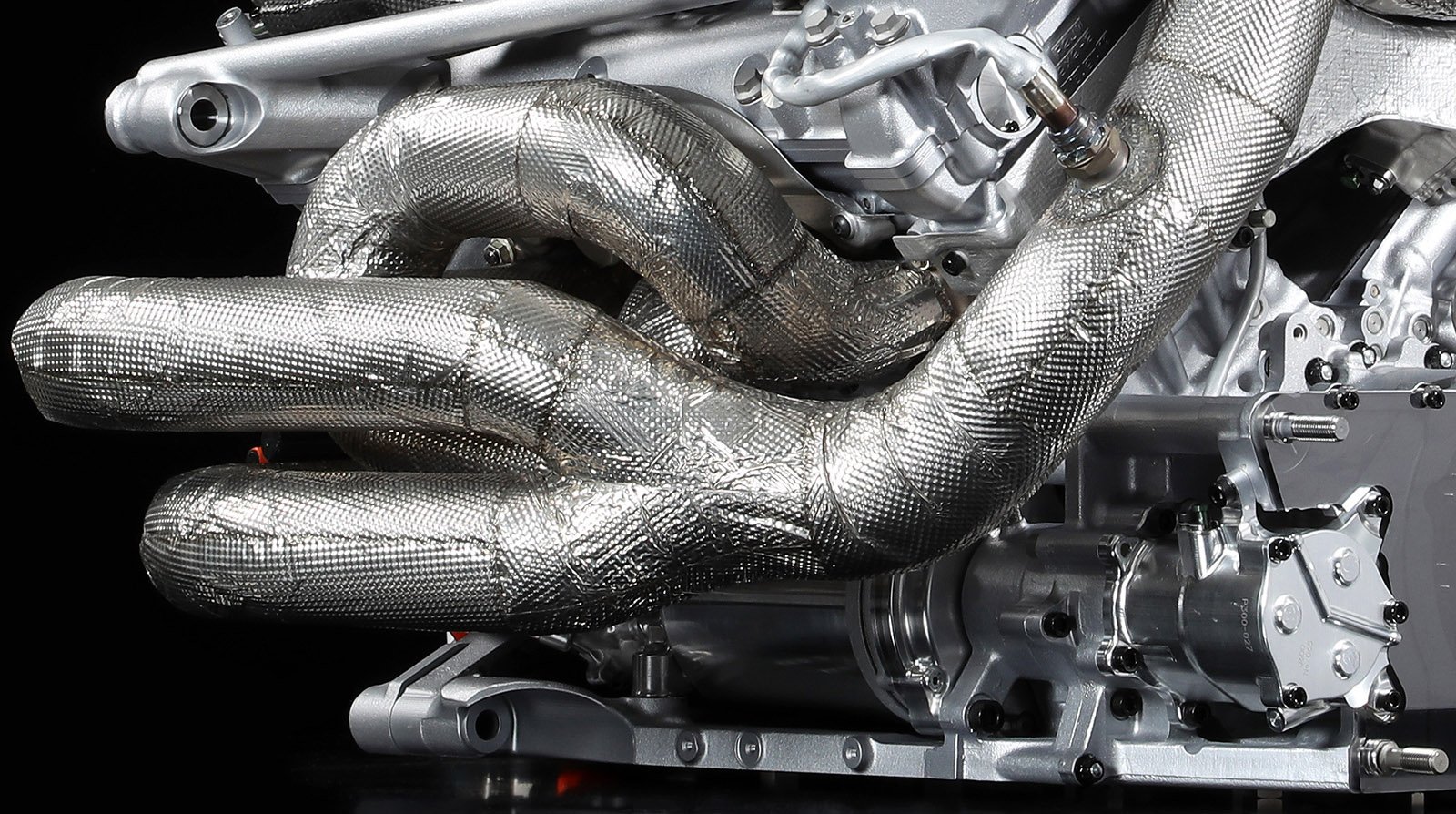

Rice Racing - Fact V FictionWe have used many different types of lambda sensors, some well known others not so. Commonly some lesser types (Non NTK) are proven the world over to be a second or third rate choice with respect to durability suffering from in tolerance to certain fuel types and operational limitations, rendering them useless for anything but the novice or hobby type user only. Now getting one to work is solved the next issues revolve around accuracy across ranges seen in various racing internal combustion engines. For the 'common' consumer grade NTK sensors they will come with a very average gross overall calibration resistor which is only a very rough trimming device used to span 'normal' operating ranges. Some lesser ECU systems rely on this which is 'easy' but far from a proper solution. They can vary + - 5% in a good one to give you some idea, this is totally unacceptable in a highly stressed application. Real quality suppliers (I mean real ones who make their own racing engines on behalf of major Automotive manufacturers) and others who supply to the highest levels of racing series around the globe, will only offer individually hand calibrated Lambda sensors, shipped out with a unique file which will then insure the said sensor is accurate and repeatable across the full span of mixtures used for internal combustion engines. ECM - ETAS - MoWreC - insert other AIDS 'claimed to be the best' - all are run by RICE RACING, the only person to ever test and own these 'in house' & now offering 'high end' services to anyone who reaches around to me. Also offering real 'unobtainium' NTK racing oxygen sensors for those who want to flex and run the highest quality real racing items. !!!BEWARE OF CLAIMZ!!!, we do this (run oxygen sensors and various 'instruments') every day! and get sent items and buy them personally! to check them, no bias, no ca$h for comments! :) FACT V FICTION - LAMBDA MASTER REAL MOTORSPORT NTK SENSORS! OPTIMIZED BY THE DON! Run up as delivered using factory NTK cal resistor and std air calibration method, IE: as run by 99.9% of users NOT VERY PROFESSIONAL BUT IT IS CAN BRO ! BUILT BY RACERS FOR RACERS - PICK A NUMBER ANY NUMBER ! NO AIDZ ! This is what Rice Racing offers, having supplied to many end users running Life Racing, Syvecs, Magnetti Marrelli, Pectel/Cosworth ECU's to name but a few quality brands. Types worked on: (NTK Only !) LZA09*, L1H1, L2H2, And we can check/calibrate your motorsport and laboratory grade NTK (various part numbers) The process of analysis and calibrationAnalysis of 'as delivered' accuracy, here is an out of the box new NTK consumer grade Lambda sensor. Very large errors across the normal ranges and horrendous errors at extreme ranges. Before calibration basics of the % of Oxygen in the AIR is evaluated by taking local measurments of the temperature/relative humidity/barometric pressure and our reference meter is set to this. Every sensor is monitored for gas temperature and hex body temperature and tested with both known reference gas and under combustion loads in a specially made gas chamber which gives uniform stable distribution. Each one is checked 4 times over multiple days to ensure a tight tolerance and repeatability to ensure the best possible calibration curve being achieved. The end results in static and dynamic gas mixture flow tests is generally a + - 0.25% range deviation. Achieving a Laboratory grade reading result for a fraction of the cost. Pictures Click to ViewVideo below showing a validation run part of the calibration curve process to make a proper lambda sensor. RR tested and developed Syvecs 8 channel lambda to can unit.

|

| Home | | About Us | | Products | | Customer Cars | | Technical FAQs | | Links |